Unfold software SCHRÖDER Unfold

Production planning made easy

Wessobrunn-Forst (Germany), 13 December 2017 – Schröder Group, leading manufacturer of sheet metal working machines, presents a new software for programming unfolds and bending sequences. Optimally adapted to the machines, SCHRÖDER Unfold simplifies and improves production planning for users of the industrial folding machines MAK 4 Evolution UD, SPB Evolution UD, PowerBend Industrial UD and PowerBend Professional.

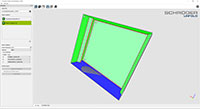

The SCHRÖDER Unfold software is able to import construction data as a Step-file (.STEP, .STP). An unfold assistant starts, giving the possibility to select material type and material thickness, machine type and available tools. The file then can be exported as DXF-file for exact cuttings or as .xml-file for a direct export into the machine software POS 3000. Thanks to its 3D-graphic the unfold assistant is very easy to handle: no previous knowledge or experience in CAD applications is necessary. The flat pattern will be designed using the bending calculations from Schröder folding machines. Thus accurate results can be ensured. SCHRÖDER Unfold has a bending radius management system, an interactive measurement of component parts and also supports swaging and welded-on pieces automatically. The software used on standard-Windows-PCs not only calculates the bending program which perfectly fits to the software control of Schröder folding machines but also the necessary cycle times. SCHRÖDER Unfold thus enables a better planning of serial productions.