Schröder folding machine at the International Roofing Expo

Pluggable profiles and perfect hems

Wessobrunn-Forst (Germany), San Antonio, TX (USA), January 30, 2025 – Represented by its partner MetalForming Inc., the Schröder Group, a leading manufacturer of sheet metal working machines, will be at the International Roofing Expo in San Antonio, Texas, from February 19 to 21, 2025. The motorized folding machine PowerBend Multi, which bends 2 mm thick sheets at a working length of 3200 mm with maximum repeat accuracy, will be on display at booth 11069. Its POS 2000 Professional graphic software control system makes it easy to operate the machine. Moreover two innovative features are its unique selling points: conical bending and the closing function for folding hems in just one operation.

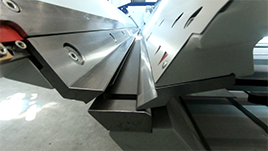

The PowerBend Multi folding machine is equipped with a rotating clamping beam. The clamping beam not only makes it possible to set up a second tool station in no time at all. It can also be set back so that it clamps the sheet metal further back. This creates space for the folding beam and a folded hem. The folding beam first creates a sharp angle, the clamping beam is set back and clamps the sheet metal. The folding beam then moves up to 190° to create a fold and press it shut. Instead of the traditional pressing with the clamping beam, the much stronger and crownable folding beam is now used for this task. This makes it possible to fold hems uniformly over the entire working length of a two millimeter thick steel sheet.

Conical bending

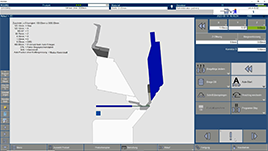

Another Schröder innovation is available on the PowerBend Multi: the electroni-cally controlled two-axis back gauge. If profiles are required that are longer than the width of the machine, simply enter the required total length in the POS 2000 Professional software control. This automatically calculates sections that have tapered edges with a precision in the tenth of a millimeter range. The result is form-fit, pluggable profiles.