Schröder Group at EuroBLECH 2022

Passion for sheet metal bending

Wessobrunn-Forst (Germany), 19 September 2022 – The Schröder Group will present ist broad portfolio of sheet metal working machines from October 25 to 28, 2022 (Booth A48, Hall 11) at EuroBLECH in Hanover, Germany. Highlights include the innovation of the fully automatic folding beam tool changer on the EVO Center and the presentation of the PowerBend Multi. The popular PowerBend Professional will be on display in its completely redesigned version with the option of a rotating clamping beam.

The EVO Center has been developed for industrial series production with the highest repeatability and offers far-reaching automation options. What Schröder is focusing on this time at EuroBLECH is the flexibility of the machine to also efficiently produce single pieces and small batches. Whereas automatic changes of the up to 400 mm high tools on the clamping beam were already possible extremely quickly with two asynchronously movable gripper units, there is now another special feature: The EVO Center has the first automatic tool changer for the folding beam. Recesses for e.g. loops that are not to be fold, can now be set as desired under program control.

Comfortable two-millimeter class

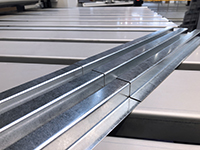

For more than 20 years, the MPB folding machine was an indispensable part of the workshops of plumbing companies. Now the Schröder Group is exhibiting the successor PowerBend Multi for the first time at EuroBLECH. The basic concept of this robust all-rounder that is processing 2-mm sheet metal at a working length of 3200 mm, got an upgrade by a number of features that could not previously be taken for granted in a machine of this class. The clamping beam of the PowerBend Multi can be equipped with tools of different heights up to 170 mm and is now also available as a rotating clamping beam, which offers a second tool station and geometry “in the blink of an eye. What was particularly important to the Schröder developers, was the space for complex workpieces in the new design – so the PowerBend Multi now has a clamping beam stroke of 160 mm, an inclined bottom beam and a retractable folding beam. An innovation from Schröder can now also used in this machine: the back gauge for conical bending in the folding technology. This enables the precise production of pluggable profiles, for example for parapet covers, roof edge trims, verge sheets or cladding with slopes. Another new feature for a machine of this class is the central crowning. The values for its setting can be stored and called up in the software together with the bending programs.

Public favourite complete again

The revised second version of the popular PowerBend Professional will be on show at EuroBlech with the optimized rotating clamping beam. Among other things, the machine has been improved with servo control and a clamping beam stroke of 500 mm as well as the possibility of using 250 mm high goat’s foot tools. Sheet metal folding with clearances is also the topic of one of the demo workpieces produced on the various machines during the exhibition: a four-piece filing cabinet that can be assembled without screws.

Other exhibition machines include the PowerBend Industrial for folding 5 mm thick sheets over a working length of four meters, the motorized shear PDC NC, the slip bending roll 134/15/2, the motorized swaging machine 416/63/1,5 and manual folding machine ASK 3.