Schröder Group at the EuroBLECH 2024

Robot controlled from a folding machine

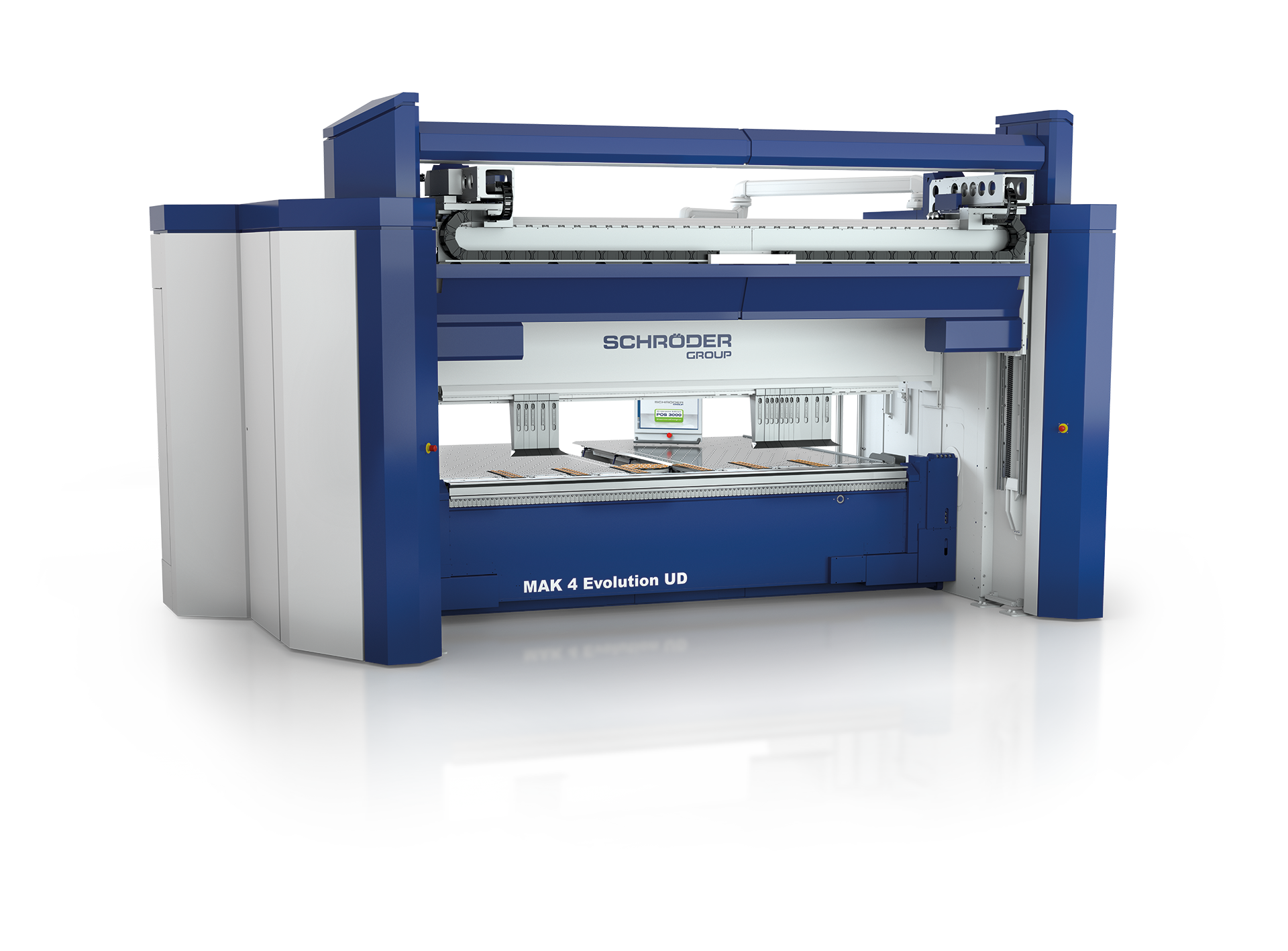

Wessobrunn-Forst (Germany), September 5, 2024 – From October 22 to 25, 2024, the Schröder Group will be exhibiting a selection of sheet metal working machines at booth 11-A48 at EuroBLECH in Hanover. With a slip bending role, a motorized shear and the flexible PowerBend Professional UD folding machine, the company will be presenting solutions tailored to the needs of the sheet metal working industry. The focus of this year’s exhibition appearance is on industrial sheet metal working machines and automation. The highlight: a MAK 4 Evolution UD with robot module in the control system, which processes heavy sheets fully automatically with a robot.

The Schröder Group has teamed up with automation specialist STARMATIK to present a system at EuroBLECH that can be integrated into fully automated industrial production processes. A MAK 4 Evolution UD has been equipped with a Fanuc robot for this purpose. It loads the machine with up to 6 mm thick sheets and 3000 x 1500 mm in size and places the finished bent product on a palletizing station. Thanks to the pneumatic stop in the Advanced Handling System and the up-and-down folding beam, the folding machine itself runs through the production process without any intervention from the robot. The entire automation solution is controlled via the Schröder software. No knowledge of robotics is required. The robot module in the Schröder POS 3000 control system will be available in future for all machines in the Evolution class and also the PowerBend series.

PowerBend Industrial UD

The Schröder Group, which is celebrating its 75th anniversary this year, has also redesigned its PowerBend Industrial UD folding machine. The machine, which can be seen at the exhibition in the version for bi-directional folding of up to 5 mm thick steel sheets to a length of 4000 mm, has been equipped with improved servo motors throughout.

Flexibility

“Automation and digitalization are definitely part of our vision for the future,” explains Thomas Ostermair, Sales Manager at Hans Schröder Maschinenbau GmbH. “However, automation and flexibility can be opposites, which is why in most cases partial automation, tool changers and rotating clamping beam as well as individual convenience functions are better suited to the requirements. Small batches and individual pieces are the real challenge, especially in the trade and for suppliers.” Another highlight of the exhibition is the PowerBend Professional UD folding machine for up to 3 mm thick sheet metal, which provides maximum flexibility for plumbing companies, for example. It is equipped with an up-and-down folding beam, rotating clamping beam for two tool stations, radius step bending function and suction plate stop. This equipment enables semi-automated production and quick set-up for individual pieces.

Robust shears for continuous use

The PDC-NC, a robust motorized sheet metal shear with NC positioning gauge, motorized blade gap adjustment and pneumatically controlled sheet holding-down device, is also part of Schröder’s EuroBLECH presentation. The version on show cuts steel sheets up to 2 mm thick, but is also suitable for other materials – the pneumatic hold-down device can be deactivated for very soft materials. Practical: With the series cutting function, up to 99 different or repetitive stop dimensions can be preset. This means that several stop dimensions can be processed in succession or repetitions can be specified for individual dimensions.