Schröder Group patent: Squeezing function

Hemming function in only one working step

Wessobrunn-Forst (Germany), Februar 6, 2024 – The PowerBend Multi (PBM) is a versatile folding machine for thin sheet metal processing. Hans Schröder Maschinebau is now presenting a patented innovation that is available for the first time with the PBM. In combination with the option of the rotating clamping beam, it is possible to fold hems in just one working step with the folding beam.

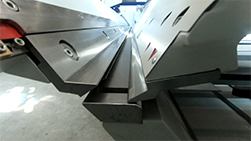

The innovation was inspired by the following motto: “What can be bent can also be pressed shut.” The clamping beam not only makes it possible to set up a second tool station in no time at all. It can also be set back so that it clamps the sheet metal further back. This creates space for the folding beam in order to fold hems. The folding beam first creates a sharp angle, the clamping beam is set back and clamps the sheet. The folding beam then moves up to 190° to create a fold and press it shut. Instead of the traditional pressing with the clamping beam, the much stronger and crownable folding beam is now used for this task. This makes it possible to to fold hems out of two millimetre thick sheet steel over the entire working length of 4000 mm.

Need a longer profile? Bend conically!

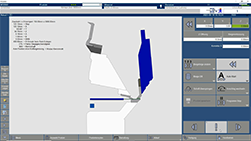

Another Schröder innovation is available on the PowerBend Multi: the electronically controlled two-axis back gauge. If profiles are required that are longer than the width of the machine, simply enter the required total length in the POS 2000 Professional control unit. This automatically calculates sections that have tapered edges with a precision in the tenth of a millimeter range. The result is form-fit, pluggable profiles.