Automation systems

Roboter Handling System

More efficiency for your series production!

A Schröder automation system with robot handling system is your industrial solution for achieving high-volume and flexible series production with extreme repeat accuracy.

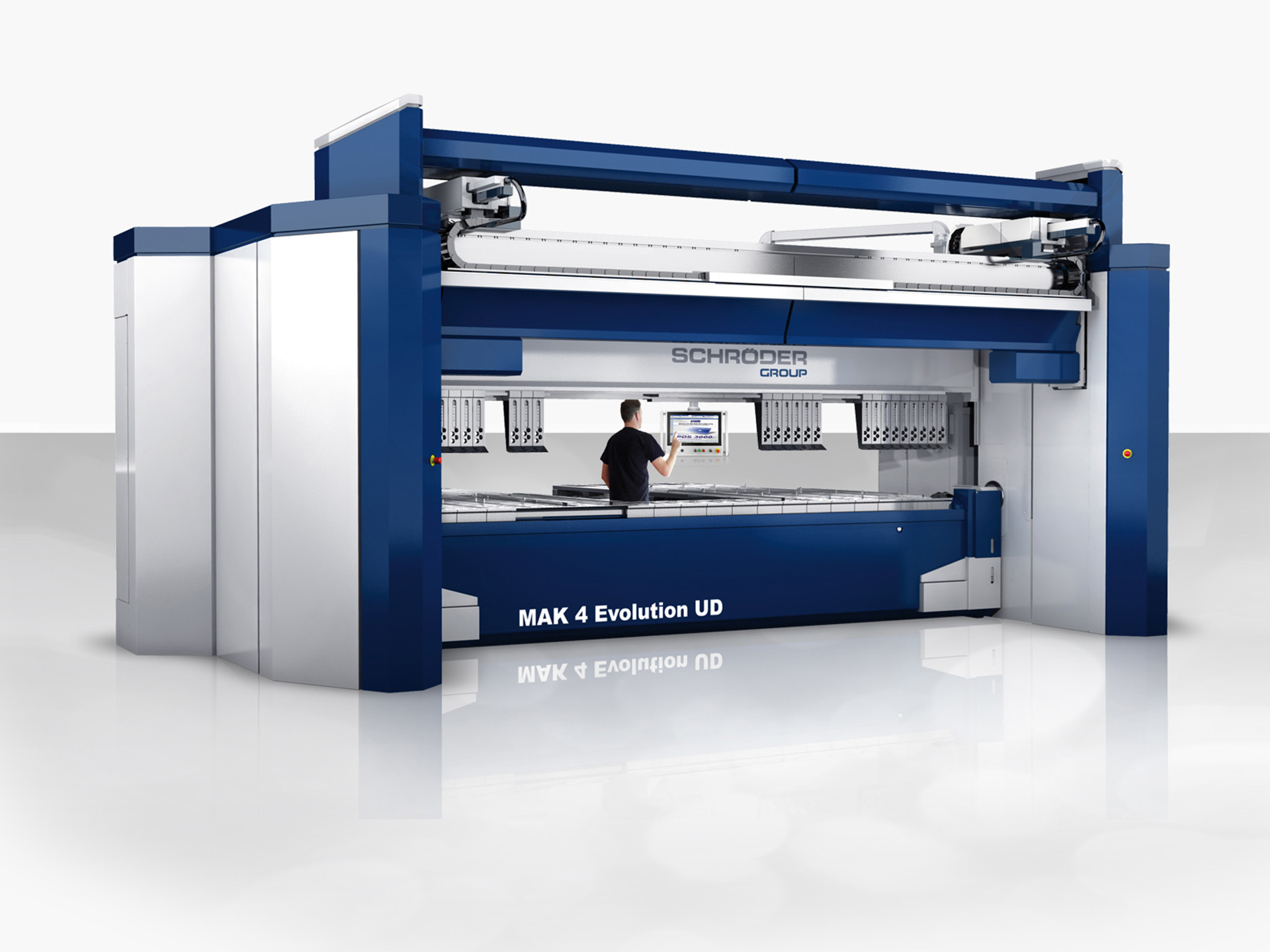

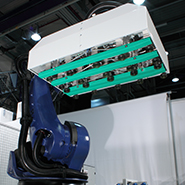

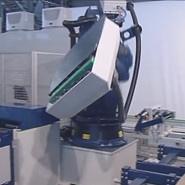

The Schröder Group has teamed up with automation specialist Starmatik to offer customers a system that can be integrated into fully automated industrial production processes. High-performance folding machines from the Evolution or PowerBend series from Hans Schröder Maschinenbau form the basis for this fully automatic and modular automation system. They are

equipped with a Fanuc robot. It loads the machine with the sheets to be bent and then places the finished bent product on a palletizing station.

Power-Bend-Center

Do you have special requirements? Do you want to produce around the clock or synchronise your sheet metal folding with other processing steps? You do not only need a machine, but also wish to have an optimized manufacturing process?

High performance swivel folding machines from Hans Schröder Maschinenbau form the basis for semi- and fully automated folding centres. The industrial sheet metal working with a Schröder-folding centre enables large volume- as well as flexible serial production with utmost repeatable accuracy.

Building on our technology, our hardware and our software, we develop individual sheet metal working solutions that range from customized machines, through various steps of automation and extend right up to complete production lines that run fully automated in 24 hours operation.

Let us show you the possiblities you have with the automation of sheet metal working.

High performance machines as core element within automation systems

Schröder automation systems are based on our modern folding machines of the Evolution- oder the PowerBend series. These machines are already fast and extremely efficient in normal operation conditions with manual product placing. In the centre of an automated solution their strength can be even more extended. Extremely robust and with very low maintenance needs these machines are perfect for continuous use.

Flexibility by automated tool changing

Thanks to an intelligent set-up handling, an automation system with a robust and also surface-protecting folding machine of the Evolution-Series can be used efficiently not only for serial production but also for the order-related manufacturing with rapid changing of small lots and single pieces. The fully-automated tool changer used on machines of the Evolution-Series equips the clamping- and the folding beam fast and error-free with tools.

Error-free and extremely fast: With one click on the software the fully-automated tool changer of the folding machine MAK 4 Evolution UD is equipping the clamping- and folding beam within a few seconds for the next order.

Let us show you which machines in which configuration form the ideal base for your automation system.

Special machines for special tasks

Swivel folding machines are highly versatile. On request, our specialists in sheet metal forming design special machines that will improve the efficiency for your individual production processes.

Challenge us. Do not only order one machine but also optimize your production process with our solutions. Special machine construction is an additional offer of the Schröder Group and in principle for each machine possible. And also for these special solutions automation steps may be possible. We offer customized construction machinery for industrial folding centres as well as for automated or semi-automated tailor-made solutions of mid-sized companies with special manufacturing challenges.

Customized solutions may include:

- adjustments on clamping- bottom- or folding beam

- special gauge solutions including software

- special dimensions

- special tools

- robotic solutions for feed-in and feed-out

- Advanced Handling Systems

Advanced Handling System (AHS) – Innovative rotating plate with suction cups

Forward withdrawal with folding table

Special gauge finger

Grip finger for automated sheet handling

Gripper arm of manipulator

Pressing unit / press brake

Your individual sheet metal solutions will be completely developed and produced in-house.

Everything out of one hand.

Control Software

Hans Schröder Maschinenbau is not only a leading manufacturer of high-end folding machines for decades, but also a pioneer in programming and control of these machines.

Automation systems are composed as customer-specific solutions. The core is the control software POS 3000 developed by us. You do not only create and simulate the folding programs in here but also control the tool changer, manipulator and delivery system.

Automation, robotics and sensor technology

In order to automate production processes we rely on established suppliers of reliable components. Fully-automated feed-in and feed-out in Schröder folding centres are based on industrial roboters of leading manufacturers.

Tables, delivery systems, gauge techniques and highly flexible manipulators bring the work pieces in the right position. Here, the work pieces are measured exactly by new camera systems – this guarantees top values for precision and repeatability for each bend.

Lightbarriers, movement- and touch sensors ensure safe operations of thefully automated sheet metal processing system.

Gripper unit for automatic loading

Pallet station for automatic loading

Advanced Handling System (AHS) – Innovative rotating plate with suction cups

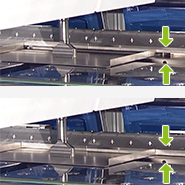

Automatic handling: The sheet metal plate is being picked up via suction units …

… and will be positioned in front of the gauge table for further processing …

… where the sheet metal plate will be gripped by special guage fingers.

Cleaning station for sheet metal plates

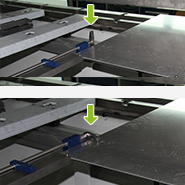

The magnetic spreader separates the sheets as they are picked up.

Double tray detection ensures that only one tray is actually loaded.

The robot arm uses a centering table.

Sheet turning device