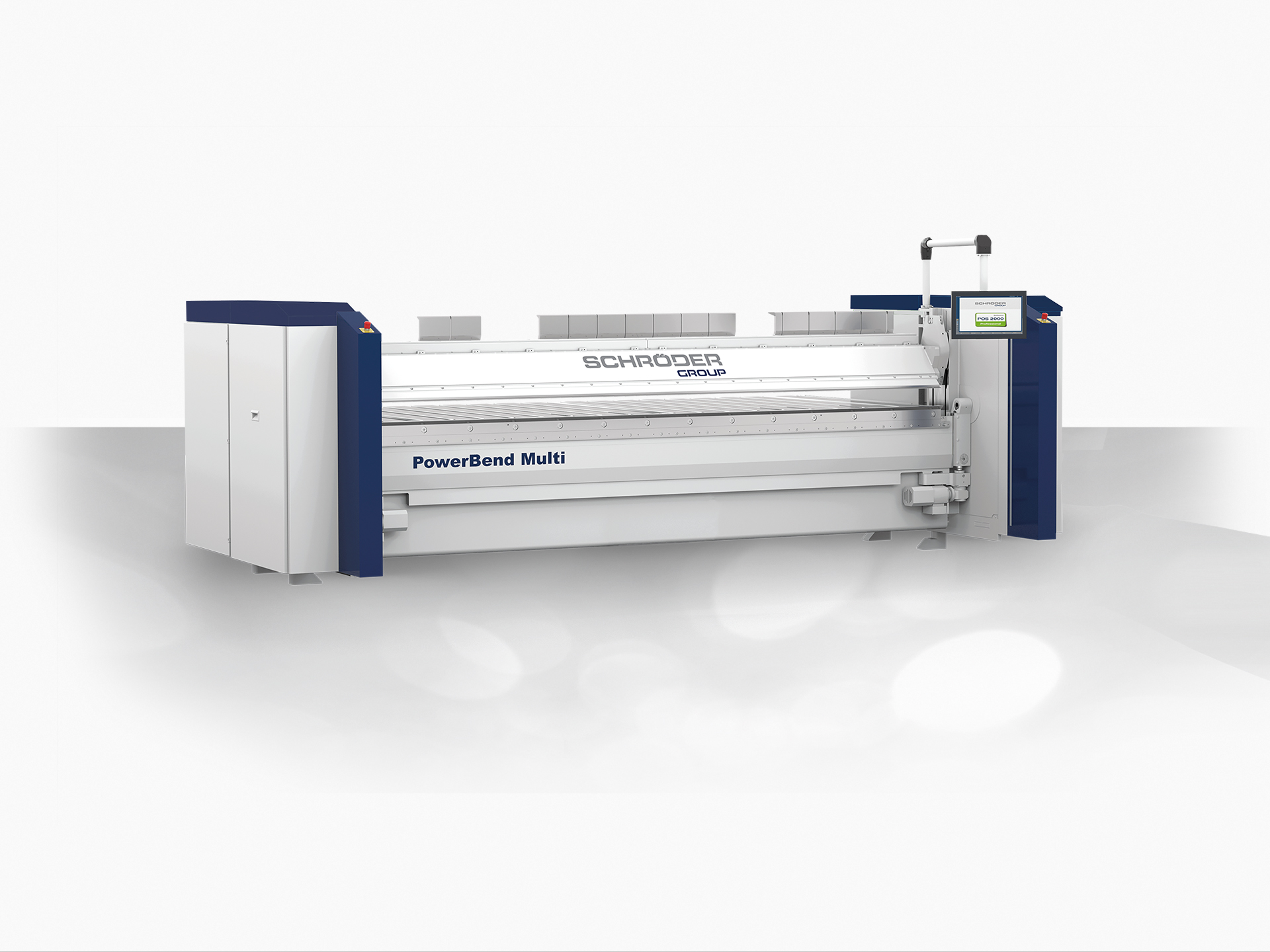

PowerBend Multi

Details

Details

- Graphic control POS 2000 Professional on swivelling arm based on Windows 10 operating system

- Radius function

- All motorized axis are converter-controlled

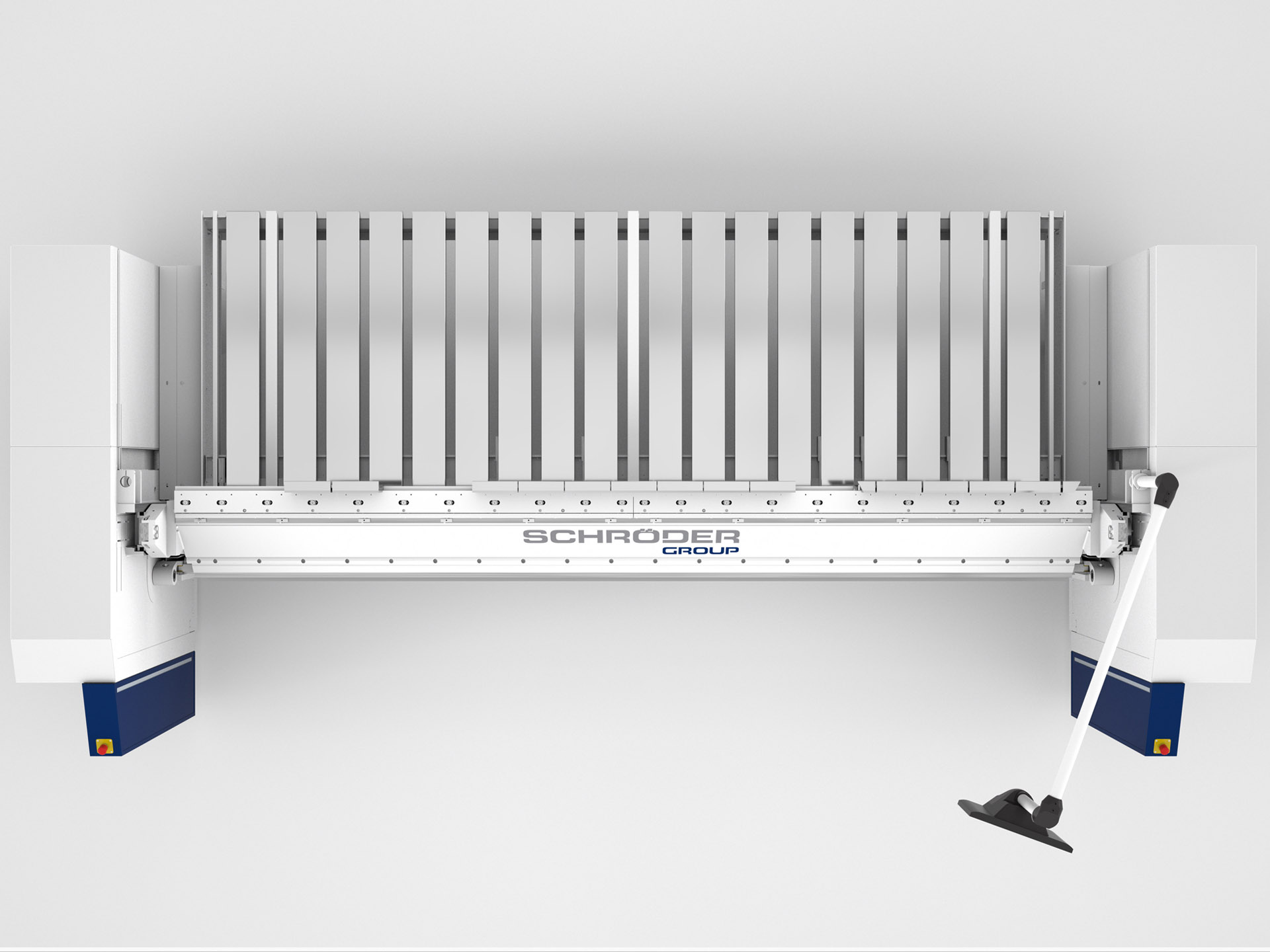

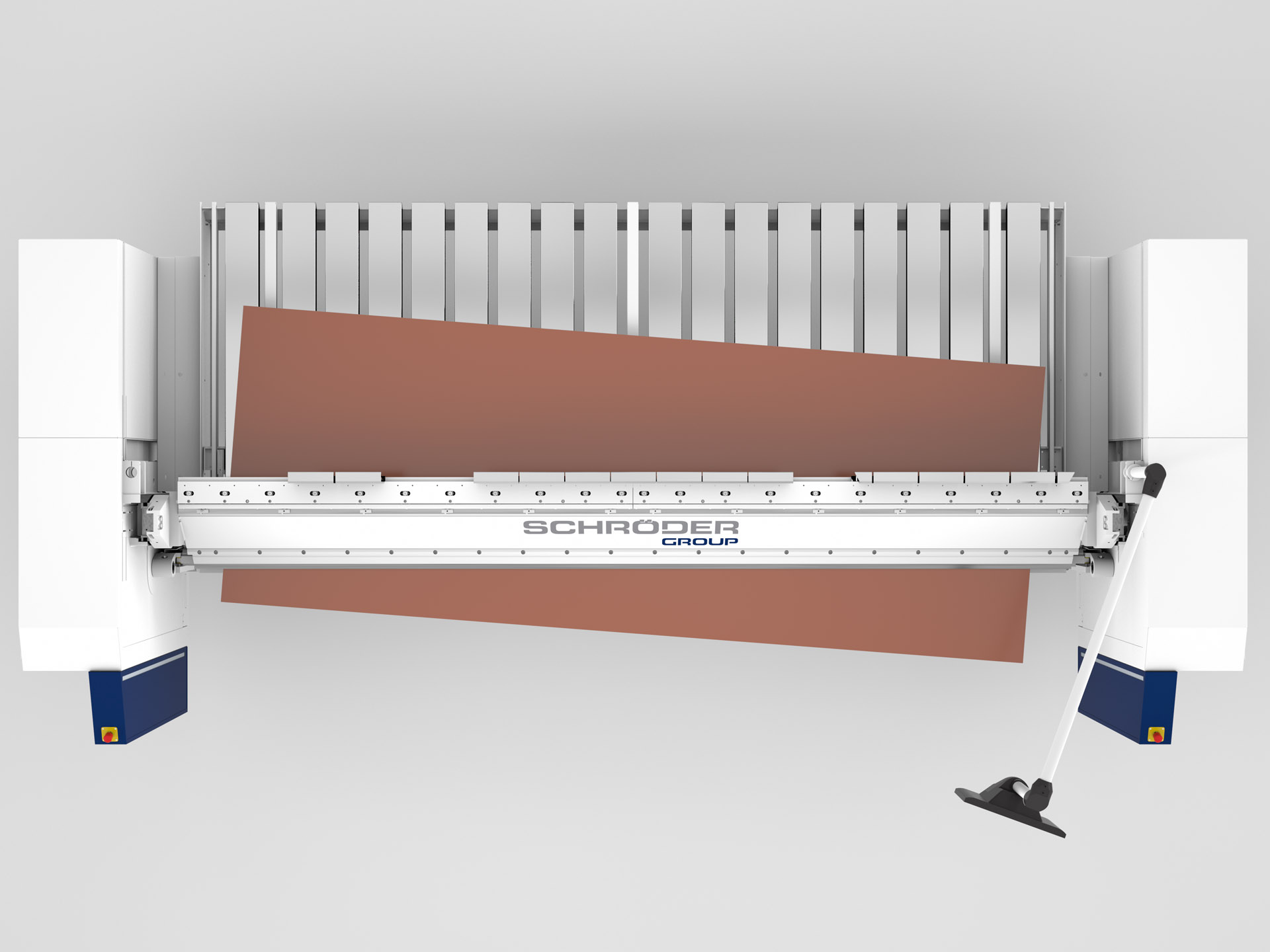

Back gauge

- Back gauge, motorized 5 – 1000 mm

- Recirculated ball screws (+/-0,1)

- 12 gauge fingers (for 2500mm or rather 3200 mm)

- 14 gauge fingers (for 4000 mm)

- Removable sheet support plates, retractable to 337 mm

Clamping beam

- Stroke 160 mm

- Geometry: 50°

- Clamping beam tools: Tinsmith blade, 20 °, R1/1,5 mm, directly screwed to the clamping beam, hardened ca. 1100 N/mm²

Folding beam

- Drive 2×2,2 kW (90°/sec)

- Folding beam moved to the back

- Manual folding beam adjustment 60 mm

- Folding blades cranked 10 mm and 25 mm (from working length 3200 mm: 15 and 25 mm)

Bottom beam

- Bottom beam blade, one-piece , ca. 700 N/mm²

from 30 mm: 8 mm lowered, with or without finger grooves

Others

- Tool cabinet with shelves

- Foot switch

Technical data

| type | capacity | working length |

clamping beam stroke |

adj. folding beam |

drive power clamping beam |

drive power folding beam |

| [mm] | [mm] | [mm] | [mm] | [kW] | [kW] | |

| 2500×2,5 | 2,50 | 2520 | 160 | 60 | 2 x 3,0 | 2 x 2,2 |

| 3200×2,0 | 2,00 | 3220 | 160 | 60 | 2 x 3,0 | 2 x 2,2 |

| 4000×2,0 | 2,00 | 4020 | 160 | 60 | 2 x 3,0 | 2 x 2,2 |

Software

Software

POS 2000 Professional – for standard industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast and comfortable. The desired program components can be selected from a comprehensive and expandable catalogue. The angle and side dimensions are easily changed by pressing the monitor.

The software control shows exactly what the machine is doing: The folding machine, work piece and tools are displayed schematically and are updated for every bending step. Anyone who is doing program planning off the machine can test the quality of their program planning by using the bending simulation. Thus mistakes and delays during production can effectively be avoided.

The software not only controls the machine, but also offers assistance to the user: all of the necessary operator activities like turning, rotating etc. are displayed for each bending step.

Tools/Options

Options

- Back gauge

- Back gauge, conical bending

- Sheet support table with balls

- Pneumatically lowerable gauge fingers

- Back gauge motorized 1600 mm, closed, with two sectors pneumatically lowerable

- U-gauge 1600 mm with two gauge sectors (1000/1600 mm) incl. pneumatic lowering device, sheet support table with balls, operation from the rear, 2nd foot switch, access security in front via light barriers + switch and button on panel

- Safety and others

- Additional equipment for 2-man-operation conrol in accordance with accident prevention rules required

- Foot switch on rail

- Light barrier Package Plus: additional light barrier in front, vertically and horizontally

- Light barrier aisle side for U-gauge 1600 mm

- Air conditioner, voltage transformer 12 kVA

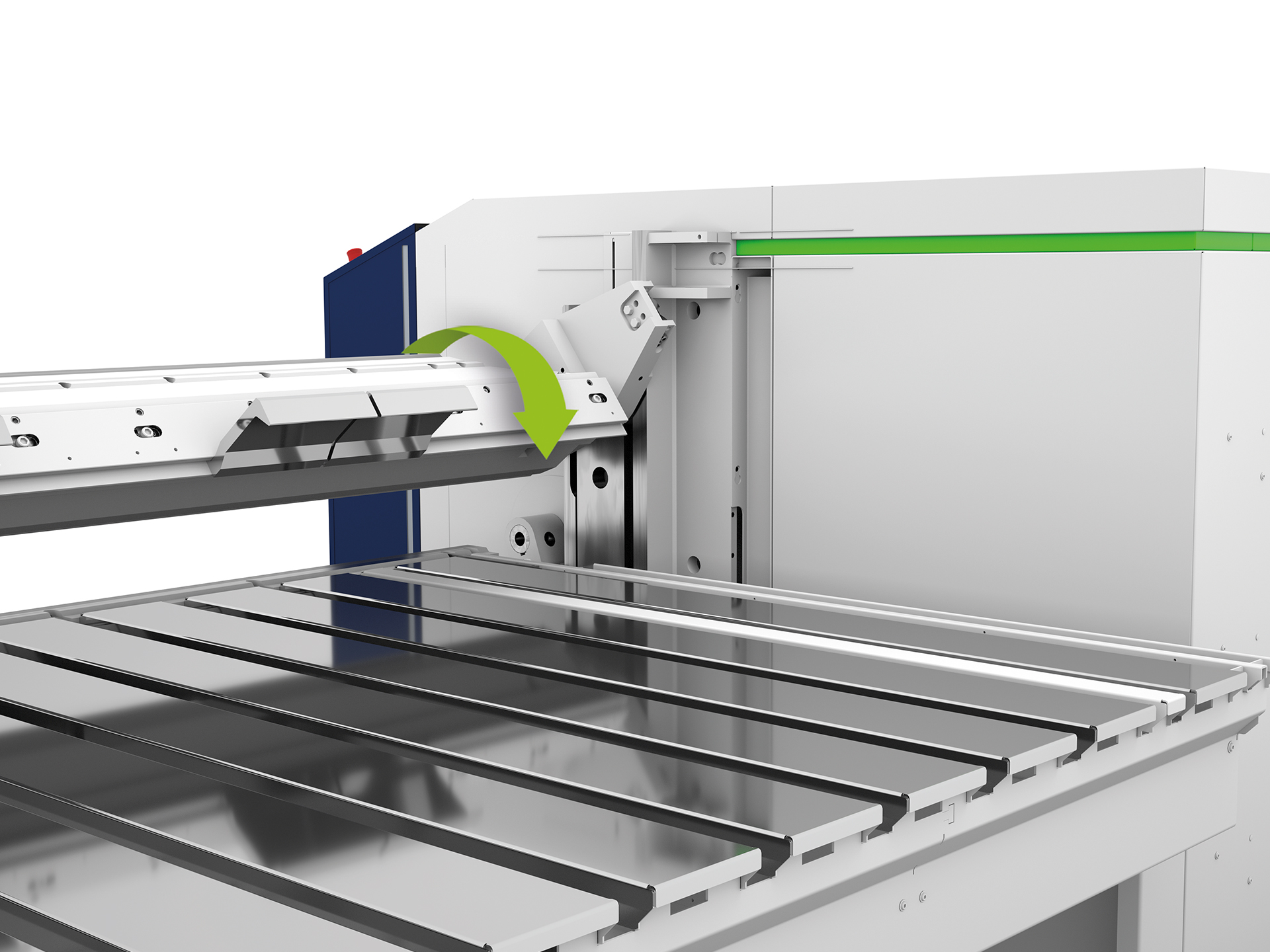

- Clamping beam

- Rotating clamping beam as automatic tool changing system incl. hydraulic tool clamping (Tool clamping only for goat’s foot tools possible)

- Goat’s foot blade H=130 mm, 30°, R 1/1,5, free space 110 mm, clearance 30 mm, foot width 50 mm, segmented incl. corner parts

- Goat’s foot blade H=170 mm, 30°, R 1/1,5, free space 150 mm, clearance 30 mm, foot width 50 mm, segmented incl. corner parts

- Clamping rail and prism bar necesssary to use goat’s foot tool and tinsmith blade, without rotating clamping beam (standard tinsmith blade is changed to tinsmith blade)

- Tooling set surface-treated mangan-phosphated

- Folding beam

- Crowning device for folding beam, manual central crowning

- Folding beam adjustment: motorized 80 mm, program controlled

- Bottom beam

- Bottom beam blade without gradation with finger grooves

- Bottom beam blade withouth gradation without finger grooves