MHSU

Details

- Manual back gauge 750 mm, adjustable from the front, with digital readout

- Hold-down device with hard rubber rail to protect polished sheets

- Telescopic support table

- All-steel blade, double-edged

- Adjustable angle gauge left and right, with scale

- Milled grooves every 10 mm along the table, parallel to the blades

- Selector switch for single and continuous stroke

- Footswitch

- Anchor plates incl. dowels

- Obligatory CE safety package for standard machines rear guarding via 3-beam light barrier incl. side protection grid

- Working height 920 mm

Technische Daten

| Type | Capacity | Working length | Cutting angle | Number of strokes | Drive power |

| [mm] | [mm] | [°] | [per min.] | [kW] | |

| 1250×4.0 | 4.00 | 1,280 | 2.0 | 34 | 4.0 |

| 1500×2.5 | 2.50 | 1,530 | 2.7 | 34 | 3.4 |

| 1500×4.0 | 4.00 | 1,530 | 2.7 | 34 | 4.0 |

| 2000×2.5 | 2.50 | 2,030 | 2.0 | 34 | 3.4 |

| 2000×3.0 | 3.00 | 2,030 | 2.0 | 34 | 4.0 |

| 2500×2.0 | 2.00 | 2,530 | 1.7 | 34 | 3.4 |

| 2500×2.5 | 2.50 | 2,530 | 1.7 | 34 | 4.0 |

| 3200×1.5 | 1.50 | 3,230 | 1.3 | 34 | 3.4 |

| 3200×2.0 | 2.00 | 3,230 | 1.3 | 34 | 4.0 |

Options

Options

- Fine adjustment screws for material with less thickness 0,5 mm

- Blades designed for stainless steel instead of standard blades

- Manual back gauge 1000 mm, adjustable from the front with digital readout

- NC positioning gauge Classic Cut Touch control on turnable panel

- Sheet support, pneumatically controlled, material to the back (supports reaching up to 10 mm to the lower blade)

- Sheet support, pneumatically controlled, material to the front incl. sheet shute, rear guarding via cover

- Version 1 Sheet support, pneumatically controlled, material to the front incl. sheet shute (Seesaw reaching up to 30 mm to the lower blade)

- Version 2 Combi-Sheet support (only in combination with ClassicCut), pneumatically controlled sheet support with the following functions:

- Unloading to the front incl. sheet shute

- Rear cross cut function incl. safety package

- Version 3 Combi-Sheet support (only in combination with Classic Cut), pneumatically controlled sheet support with the following functions:

- Unloading to the front incl. sheet shute

- Unloading to the rear with stacking function

- Seesaw with plastic rolls

- Sheet support to the front, with gauge extension up to 1000 mm

- 2 sheet support arms with T-slot incl. scale (standard telescope table is dropped)

- Extended angle gauge (right or left) with scale

- Extended angle gauge (right or left) with scale incl. lateral tipping gauge on linear guide

- Extended angle gauge (right or left) with electronic length measurement system, finei adjustment and lateral tipping gauge on linear guide

- Adjustable angle gauge with scale division 0 – 180°

- T-slot in table 400 mm

- Tipping gauge for insertion in T-slot

- Linear guide at the front for movable table support arms (without support arms)

- Movable support arm for linear guide, at the front, incl. T-slot and scale

- Longlife bearing system, driving rod with self-aligningroller bearing, connecting rods with needle bearing

- LED cutting edge illumination

- Pneumatic hold-down device

- Stroke counter

- Extended sheet shute to the front

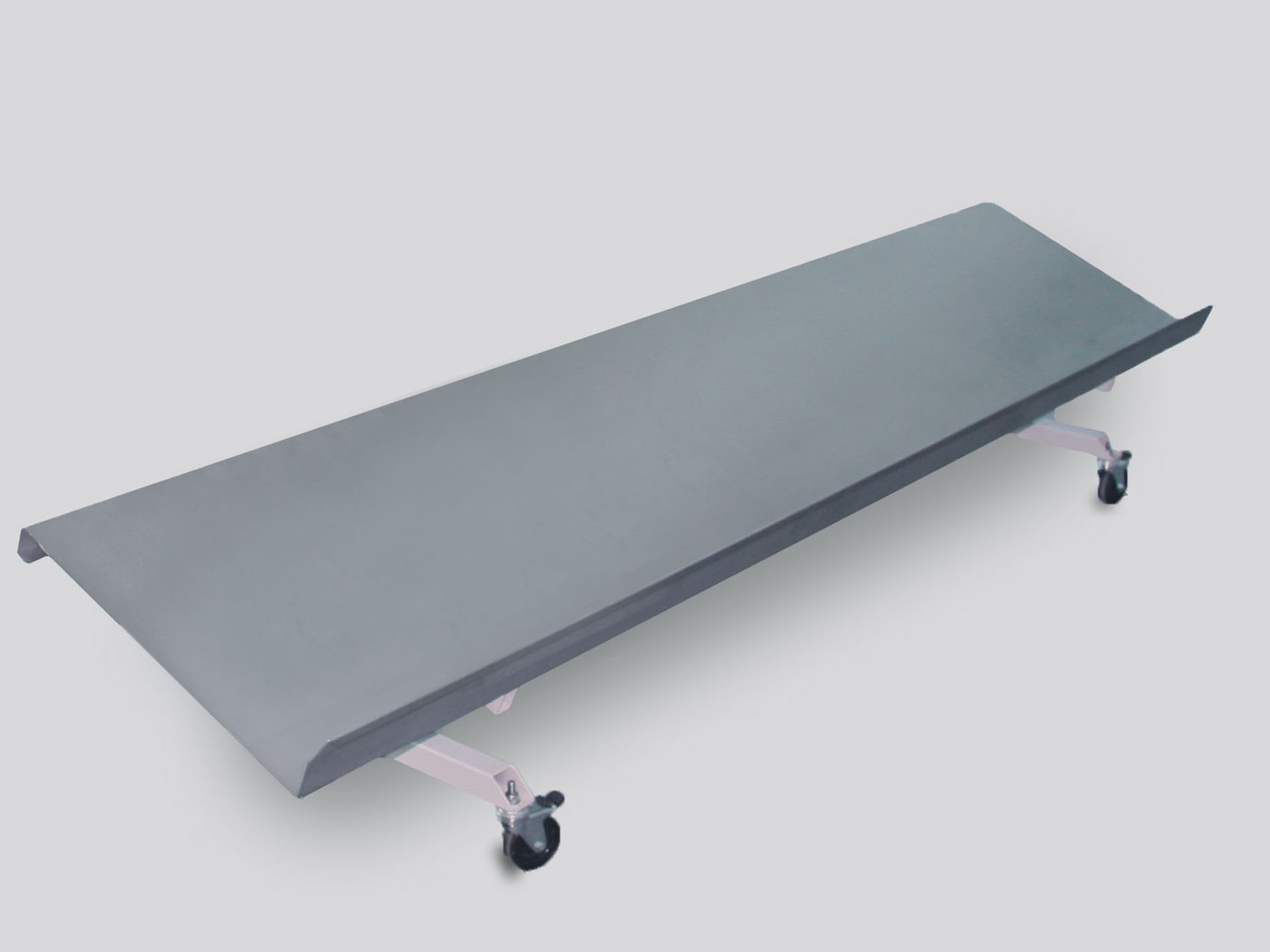

- Slide cart on 4 steering castors, 2 lockable

(for cuttings up to max. 500 mm up to max. 200 kg) - Sliding cart (without stacking sheet insets) usable for depostion to the front, optionally to the back with 4 steering castors, 2 lockable

(for cuttings up to max. 750 mm up to max. 400 kg, only in conncection with sheet support) - Set of stacking sheets for sliding cart, maximum stacking height 30 mm

- Ergonomic stacking cart frame-guided on steering castors for combi sheet support for stacking to the rear at a height of 675 mm, max. load 400 kg, stacking height ca. 100 mm