| Name | Short description | Sheet thickness up to |

Working length max. | ||||

|---|---|---|---|---|---|---|---|

| Name 102 | Short description The small slip bending roll machine type 102 is suitable for construction sites as well as for repair shops. Because of its high accuracy it is also often used in model workshops or training centres. | Sheet thickness up to up to 1.5 mm | Working length min. up to 1000 mm | Link | ||

| Name 114 | Short description The machine type 114 is an automatic NC controlled slip bending roll with hydraulic pre-bending roll adjustment as standard. | Sheet thickness up to up to 3 mm | Working length min. up to 2000 mm | Link | ||

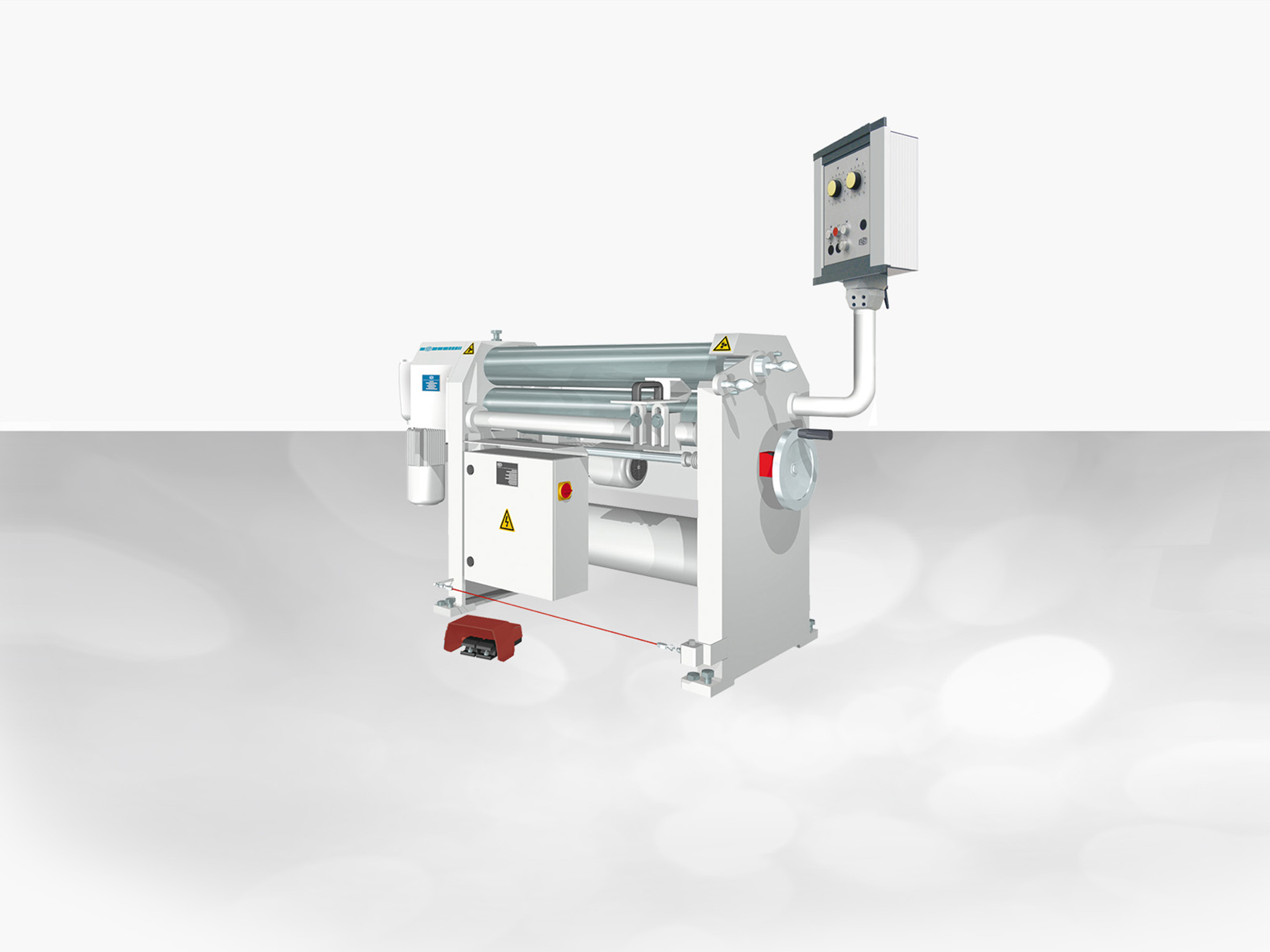

| Name 125 | Short description This power-operated slip bending roll is a reasonable alternative to the hand-operated machine type 102. The solid engineering guarantees the necessary continuous accuracy for manufacturers of small bulks. | Sheet thickness up to up to 1.5 mm | Working length min. up to 1000 mm | Link | ||

| Name 134 | Short description Prerolling and final rolling in one machine! With its special roll concept, wide range of accessories and robust design, this is the machine for truly universal and cost-effective work on single jobs and in series production. | Sheet thickness up to up to 4.5 mm | Working length min. up to 2000 mm | Link | ||

| Name 136 | Short description Thanks to the associated asymmetrical roll arrangement, the result is unprecedented rolling quality. With its special roll concept, wide range of accessories and robust design, this is the machine for truly universal and cost-effective work on single jobs and in series production. | Sheet thickness up to up to 6.5 mm | Working length min. up to 2500 mm | Link | ||